|

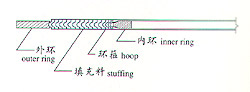

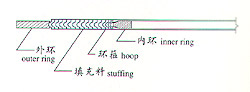

- Structure

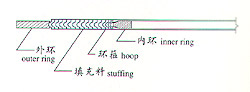

The metal wound gadket is made of "V"-shaped or

"W"-shaped metal ribbon and non-metal ribbon

by continuously overlapping and winding.Both ends of metal ribbon

are spot welded.

- Features

(1) It is xuitable to wide application,high temperature

resistance,high pressure resistance

as cryogenic and vacuum condition.The combination of gasket

material can be modulated to meet

chemical corrosion resistance requirement.

(2) High stress compensation capability.Constant and reliable

sealing even at working position

under a fluctuated pressure and temperature.

(3) Perfect sealing performance.

(4) No overstrict requirement on the surface of flanges.

(5) Easy installation and low pre-tightening specific pressure.

- Gasket Types:

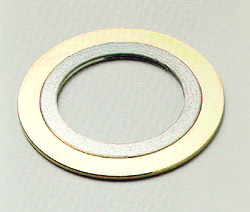

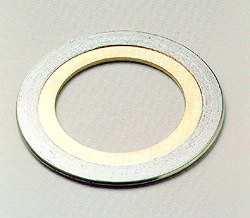

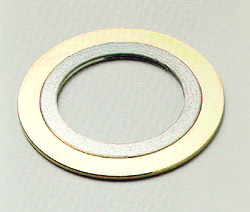

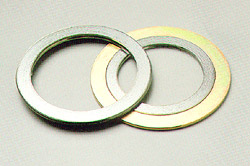

(1) There are four types:Hy-6035 Basic type gasket for motched

joint flange;Hy-6036 gasket with

inner ring for raised face flange;Hy-6037 gasket with outer ring

for smoothing flat welded flange

and ;Hy-6038 gasket with inner and outer rings for smoothing butt

welded gasket.

(2) The material:

(A) steel ribbon:304,1Cr18Ni9T(321),316 and 316L,etc.

(B) Ring:mild steel,oCr13,oCr18Ni9,304,316 and 316L,etc.

(C) Non-metal ribbon:flexible graphite,special-purpose

asbestos,Teflon and non-asbestos sheet.

- Application

(1) Working temperature: -196℃

to 700℃

( not higher than 600'C in oxidative medium )

(2) Working pressure: ≤ 25MPa

(3) Gasket coefficient: m=2.5 to 4

(4) Minimum pre-tightening specific pressure: y=68MPa

|

|